Guide: Ford GT40 Mk3 - a Historical & Technical Appraisal

/BACKGROUND

When the FIA announced that new racing classes would be introduced for the 1966 season, Ford decided to attack two different categories.

The seven-litre Mk2 GT40 was developed to contest the premier Group 6 Prototype class.

The 4.7-litre Mk1 GT40 was assigned to the Group 4 Sports category.

Unlike Group 6 where there was no minimum production requirement or engine limit, Group 4 permitted engines no greater than five-litres and 50 cars had to be built to qualify.

To meet the 50 car threshold, Ford Advanced Vehicles (FAV) began to offer customer GT40s. Deliveries began in spring 1965 and Group 4 homologation was approved on February 2nd 1966.

As it seemed unlikely there would be sufficient public demand for 50 racing cars, Ford also offered the Mk1 GT40 in road-going trim. These cars typically came with detuned engines and more comfortable interiors. 31 were ultimately built.

After the Mk2 won the Le Mans 24 Hours in 1966, Ford sold the FAV facility in Slough, along with the GT40 production rights. They were purchased by John Wyer who had managed the operation since its inception.

However, Ford had not abandoned racing. Instead, for 1967 they switched focus to the all-American Mk4.

Ford sold FAV’s fixed assets to Wyer at a give-away price and payment was deferred until the end of 1967. Wyer’s organisation (John Wyer Automotive Engineering) was also paid $250,000 a year for three years to provide parts, technical services and racing support to GT40 owners. New GT40s could be built, albeit with a fixed profit of £1000 per car.

On January 1st 1967, the staff previously employed by the Ford Motor Company became workers for John Wyer Automotive Engineering (JWAE).

Despite the split, Ford still had a desire to capitalise on their 1966 Le Mans victory. They decided to offer a more refined GT40 road car than the competition-inspired Mk1.

Importantly, the new machine would need to conform to incoming US regulations regarding minimum height for headlights and ground clearance. It would also have to meet the latest emissions regulations.

All of these were problems for the existing MK1 in road-going trim.

In early 1967, Ford commissioned JWAE to develop the Mk3 GT40.

To broaden its appeal, the Mk3 would be offered in both left and right-hand drive - so far all other GT40s had been right-hand drive. The Mk3 also differed both visually and mechanically from the Mk1.

Assembly would take place in England with Ford responsible for marketing and distribution.

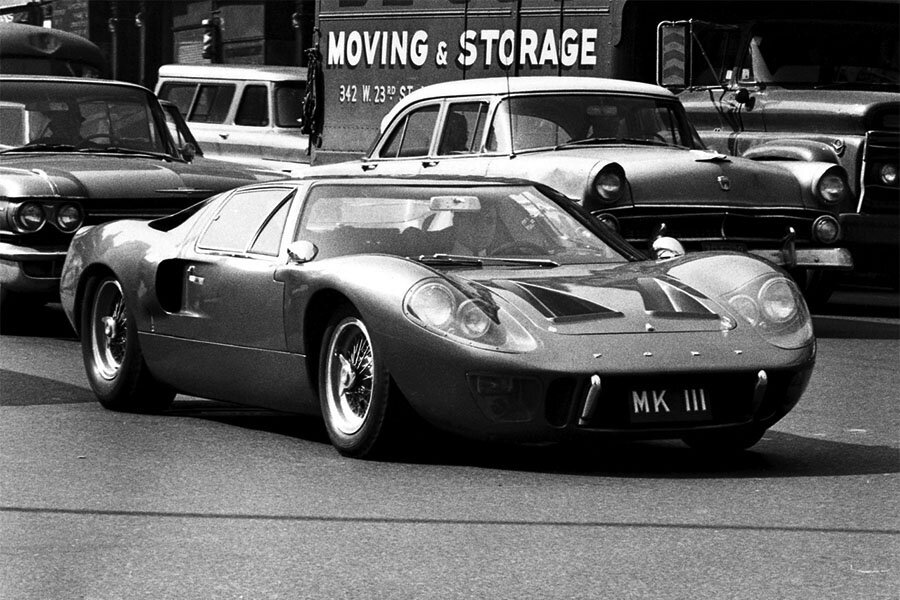

The first of two prototypes was completed in December 1966. The Mk3 then made its public debut at the New York Motor Show in April 1967.

CHASSIS

The Mk3 was based around the usual GT40 steel semi monocoque chassis fabricated by Abbey Panels in Coventry. However, the spaces between the double skinned sections were filled with polyurethane foam that absorbed noise, heat and, in the event of a crash, energy.

Suspension was essentially the same as other GT40s with double wishbones at the front and dual trailing links, transverse top arms and inverted lower wishbones at the rear. Coil springs with adjustable dampers were fitted all round along with anti-roll bars at either end.

The Mk3 featured alterations to the geometry that resulted in slightly more anti-dive, anti-lift, anti-squat and ground clearance. Rubber bushings were used for the suspension mounts. The spring, shock and roll rates were all softened.

Solid 11.5-inch disc brakes were fitted at the front. Those at the rear were 11.2-inches.

Borrani supplied the 15-inch diameter wire wheels. These centre-lock rims measured 6.5-inches wide at the front, 8-inches wide at the back and originally came shod with Goodyear tyres.

To improve corrosion resistance, the hub carriers were manufactured from alloy instead of magnesium.

The Mk3 also came with a new rack and pinion steering system.

To reduce the fire hazard in the event of a crash, a pair of smaller 13.8 gallon baffled aluminium fuel tanks were surrounded by a two-inch layer of polyurethane foam. They replaced the 18.5 gallon rubber tanks found on other GT40s.

ENGINE / TRANSMISSION

In the engine bay was a dry-sumped overhead valve pushrod 90° V8 with iron black and head. Similar to the unit found in Shelby’s GT350 Mustang, it displaced 4737cc thanks to a bore and stroke of 101.6mm and 72.9mm respectively.

A single four barrel 715 CFM Holley carburettor was mounted on a Cobra high-rise manifold.

A 10.5:1 compression ratio was employed.

Peak output was 306bhp at 6000rpm and 329lb-ft at 4200rpm.

A new exhaust system with additional silencing replaced the standard Mk1’s spaghetti affair. It exited either side of the gearbox and allowed space for luggage boxes (which had a tendency to get very hot).

A high efficiency radiator with twin cooling fans meant the Mk3 was suitable for city driving.

Transmission was via the usual five-speed ZF 5DS-25 all-synchromesh gearbox, a twin-plate Borg & Beck clutch and a limited-slip differential.

BODYWORK

By far the most obvious difference between the Mk3 and other GT40 derivatives was the new car’s bodywork.

Increasing ground clearance to meet new regulations was a relatively straightforward affair, but repositioning the headlights further up the front fenders had a drastic affect on the Mk3’s appearance.

Instead of one rectangular lens per side, the Mk3 featured a dipping headlight and a long-range spot light. The fenders were re-profiled and the nose was extended. The front lid also featured re-shaped cooling vents and a lockable hinged lid.

Other new equipment included a high-impact-resistant laminated windscreen, burst-proof door catches and chrome bumperettes at either end.

At the back, the tail was extended in order to free up enough space for the modest luggage bins.

Overall, the Mk3 was 265mm longer than the Mk1.

As usual, body panels were manufactured from fibreglass.

INTERIOR

Inside, although general fit and finish was improved, the Mk3 GT40 left much to be desired considering it was one of the most expensive motor cars of its day.

Cheap Restall seats with integrated headrests were upholstered in full or partial leather and could only be adjusted fore / aft.

Safety features were limited to inertia reel seat belts and some extra warning lights on the dash.

Padded A pillars and sun visors were new while extra sound deadening and thicker carpet insulated the cockpit from the worst of the noise.

Flip open side windows were hinged at the front. An improved heating / ventilation system was also adopted.

Directly behind the three-spoke steering wheel was a large tachometer flanked by smaller gauges for oil pressure and water temperature. Off to the centre were more small read outs for fuel, oil temperature and battery condition. A large 200mph speedometer was angled towards the driver at the far end of the instrument binnacle.

The aforementioned centrally-mounted gear lever was located between the seats to enable production of both left and right-hand drive examples.

OPTIONS

Optional extras included tinted glass, a radio, cassette player, air-conditioning and even a TV.

WEIGHT / SUMMARY

Weight was a quoted 1060kg.

Ford claimed a top speed of 160mph and 0-62mph time of 6.2 seconds.

PRODUCTION

The Mk3 prototypes (chassis M3/1101 and M3/1102) were built at a cost of $70,000 each.

Production versions were advertised at $18,500, which was $2000 more than a Mk1 racing car.

Although the Mk3 was praised by road testers for its speed and handling, much criticism was aimed at the build quality and particularly the gear change; by relocating the gear linkage from the right-hand side of the cockpit to the centre, it put up noticeably more resistance and was difficult to change cleanly.

In the end, just seven Mk3s were built between December 1966 and June 1969. Only three of these were sold to customers.

Chassis M3/1103 went to Max Aitken Jr. in London who was the Chairman of Beaverbrook Newspapers which owned the Daily Express.

Chassis M3/1104 was sold to Joseph Chandler in Florida.

Chassis M3/1105 was purchased by the renowned Austrian conductor, Herbert von Karayan.

The other four Mk3s were all retained for promotional use. M3/1101 and M3/1106 went to Ford in the USA, M3/1102 was kept by JWAE and M3/1107 was acquired by Ford UK.

Text copyright: Supercar Nostalgia

Photo copyright: Ford - https://www.ford.com & Petersen Automotive Museum - https://www.petersen.org/