B Prod. Hot Rod - a Historical & Technical Appraisal of the Ford Shelby Mustang GT350 Series 1 (1965 / 1966 MY)

/BACKGROUND

Ford’s Total Performance programme of the 1960s spawned some legendary machinery of which the four-time Le Mans winning GT40 is particularly revered.

The company’s engines were also used to power Jim Clark’s 1965 Indy 500-winning Lotus and considerable support was put the way of Carroll Shelby for his Cobra endeavours.

Later there was the dominant Cosworth DFV F1 engine (bankrolled by Ford UK) plus saloon racers and rally cars too.

While all this came at considerable expense, Ford capitalised by extending the Total Performance programme to include a stunning new high performance production model called the Mustang.

Originally conceived as a two seater, Ford senior executive, Lee Iacocca, realised the new car would be a massive seller if it could be made into a four-seater suitable for everyday use. Ford agreed and the move paid off. 22,000 Mustangs were sold on the first day of availability in April 1964 and more than 100,000 had rolled off the production line within four months.

Inside two years, over one million Mustangs were sold - it was well on the way to becoming Ford’s biggest seller since the Model T.

Based on conventional Ford underpinnings, the chassis, suspension and drivetrain components were all derived from the Falcon and Fairline. The chassis itself was a unitary platform sourced from the 1964 Falcon.

In August 1964, Ford commissioned Carroll Shelby to produce a further uprated Mustang that could rival Chevrolet’s Corvette, albeit in a more practical day-to-day package.

Shelby’s operation would also handle a competition programme attacking the SCCA’s high profile B-Production championship. 100 specially developed base cars derived from the contemporary Mustang would be needed to qualify for homologation.

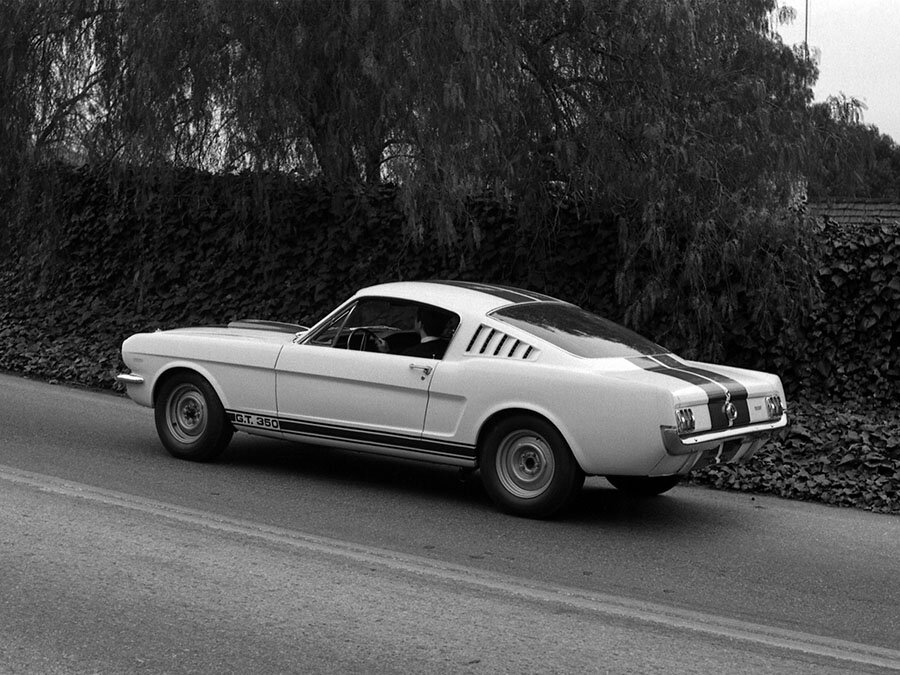

The result was the Shelby Mustang GT350, all examples of which initially started life as Wimbledon White K-Code DSO Fastbacks with 271bhp 289 cubic inch V8s and black interiors.

DSO referred to Domestic Special Order - the unique blend of upgrades these cars were built with before being dispatched to Shelby.

For example, the front disc brakes were kept, but sintered metallic pads were used instead of the softer stock items. At the rear, station wagon drum brakes with larger metallic-lined shoes were installed.

There were also 9-inch Detroit Locker limited-slip differentials, under-hood ‘Export’ bracing and close-ratio T-10 Borg Warner four-speed gearboxes with special lightweight aluminium casings.

Cars were shipped from Ford’s San Jose plant to Shelby American’s Los Angeles facility without hoods, grilles, rear seats, exhaust systems or emblems.

Then the transformation really began.

The SCCA’s B-Production rules stated that qualifying cars could run either modified suspension or engines, but not both. Shelby opted for the modified engine route and thus the suspension was created from existing Ford components.

To meet the SCCA’s 100-car production requirement, Ford initially only shipped the required number of their specially optioned Mustangs to the Shelby American plant.

By September 1964, the first GT350 had been built.

The remainder were ready for inspection by December ‘64 and homologation was duly granted in January 1965. Shelby American then moved to its new production facility at the Los Angeles International Airport.

The GT350 made its public debut at a Riverside press launch on January 27th 1965 where it appeared alongside the further uprated GT350-R for racing use.

CHASSIS

The front-suspension mounting points were re-positioned and the A-arms were lowered which reduced ride-height at the front by an inch. The live rear axle was held in place with a semi-elliptical leaf spring and stronger torque reaction arms on top of the axle itself.

Adjustable Koni shocks were installed plus new rear traction bars and thicker anti-roll bars.

Shelby further enhanced the GT350 with a quick-ratio steering rack and an oil cooler for the differential.

The stock Mustang radiator was replaced with a much bigger unit from the air-conditioned Galaxy 500.

The battery was initially repositioned from under the hood to the trunk.

15-inch wheels were available in two styles: white-painted steel or cast magnesium Crager rims. Both types originally came shod with Goodyear Blue Dot tyres.

ENGINE / TRANSMISSION

Engines were based on Ford’s new Hi-Po 289 small block V8 that produced a respectable 271bhp direct from the factory. This pushrod-operated all-iron motor displaced 4727cc thanks to a bore and stroke of 101.6mm and 72.9mm respectively. The compression ratio was 10.5:1.

Once on Shelby’s production line, each motor was equipped with a new aluminium Cobra hi-rise intake manifold to replace the stock cast-iron item.

A Holley four-barrel 715-cfm carburettor was designed not to starve or flood during hard cornering.

There were lightweight tubular Tri-Y exhaust headers that fed straight-through pipes and low restriction glass-pack mufflers. The exhausts were re-routed to exit ahead of the rear wheelarches.

Engines were dressed with a chrome air cleaner, finned aluminium Cobra rocker covers and a cast aluminium oil pan.

All told, the revamped motor produced 306bhp at 6000rpm and 329lb-ft at 4200rpm.

This compared to 271bhp at 6000rpm and 312lb-ft at 3400rpm for the off-the-shelf 289.

Transmission was via the aforementioned close-ratio Borg Warner T-10 four-speed gearbox complete with special lightweight aluminium casing, a nine-inch Detroit Locker limited-slip differential and a single-plate clutch.

BODYWORK

The GT350 was only offered in one exterior colour scheme: Wimbledon White

To save weight, the hood was manufactured in fibreglass. It also got a bulging new intake scoop and quick-release fastening pins.

Aside from a small Mustang logo in one corner, the new mesh front grille was left unadorned to maximise airflow into the engine bay.

Otherwise, this was the same incredibly handsome Mustang Fastback that had already sold in massive numbers. Smaller, more delicate and better proportioned than most sporting American cars of the time, with elegant modernist lines that appealed in any body style, the Pony Car had become an overnight icon.

Aside from the aforementioned GT350-specific fibreglass hood, body panels were fashioned from steel.

INTERIOR

The dash was modified to incorporate a GT350-specific pod that housed a large rev counter and small oil pressure gauge.

Directly behind the new wood-rimmed three-spoke steering wheel was a regular Mustang instrument binnacle with small circular dials for fuel and water temperature outboard of a flashy sliding speedometer.

Competition Ray Brown safety belts were combined with otherwise standard Mustang seats.

As the SCCA B-Production requirements only permitted two-seats, Shelby received all cars from Ford without back seats. They were instead fitted with a simple fibreglass panel that held the spare tyre in place.

Black leatherette vinyl was used to upholster the dash, seats, door panels, sidewalls and the rear storage platform that housed the spare wheel.

Luxuries were thin on the ground and manual window winders were fitted.

OPTIONS

In addition to a set of Crager wheels, customer could request Guardsman Blue centre stripes with matching GT350-branded decals for the rocker panels.

GT350-R

Customers could also opt for a full blown competition version: the Shelby GT350-R.

These cars (covered in detail separately) came with a blueprinted 350bhp un-silenced engine, modified bodywork, stripped-out interiors with a full complement of safety / racing gear, a long-range fuel tank and Torq-Thrust wheels.

The GT350-R had its first race on February 14th 1965 when Shelby development driver Ken Miles swept to victory in all the B Production races that day.

As expected, the GT350 went on to dominate the SCCA B Production Championship in 1965. The title was won by Shelby’s Jerry Titus.

WEIGHT / PERFORMANCE

At 1265kg, some 102kg had been cut from the stock Mustang.

The GT350 had a top speed of 138mph and 0-62mph time of 6.4 seconds.

For comparison, a bare bones manual gearbox K-code Coupe with an optimised rear axle ratio could do 126mph and hit 0-62mph in 7.1 seconds.

1965 MODEL YEAR PRODUCTION CHANGES

Early on during the second half of 1965 model year production the battery, which had initially been re-located from the engine bay to the trunk in the interest of weight distribution, reverted to the standard Mustang’s front-mounted arrangement.

1965 MODEL YEAR PRODUCTION

1965 model year production finished on July 9th.

526 examples had been completed, all of which were left-hand drive.

1966 MODEL YEAR

The first 252 GT350s to emerge during the 1966 model year became known as Carry-over cars as they were 1965 model year chassis built into 1966 model year cars with a unique blend of 1965 and 1966 features.

By August 1965, production of the proper 1966 model year version was underway. It went on sale in October 1965 having undergone a variety of changes, primarily because Ford wanted to make more money.

Most significantly, the rear seats were re-instated and a wider choice of colours was offered.

The 1966 model year also saw the introduction of a Hertz rental version followed by a supercharged GT350 and even a tiny number of Convertibles (all of which are covered later).

1966 model year GT350s were completed with 14-inch wheels instead of the 15-inch rims used beforehand.

The GT350-specific lowered A-arms used in 1965 were ditched for standard parts and the rear traction bars originally installed over the axle were exchanged for less complex units that now went underneath.

Outside, the elegant sail panel extractor vents were replaced with Plexiglas quarter windows. The fuel-filler cap now bore a Cobra logo rather than a Mustang emblem.

To further broaden the GT350’s appeal, four new exterior colours were introduced: Ivy Green, Candyapple Red, Sapphire Blue and Raven Black. All colours could be specified with contrasting stripe kits.

Customers could also select a set of new chrome-rimmed Magnum 500 wheels.

Although the rear seats officially returned, 95 cars from the 1966 model year were built as two-seaters.

Other cockpit changes saw an oil pressure gauge added to the instrument panel while the 1965 instrument pod was discontinued in favour of a separate tachometer mounted on the dash.

HERTZ GT350

In November 1965, Shelby made a proposition to the Hertz car rental firm about producing a special edition GT350 that would serve as a useful publicity tool for both companies.

Hertz liked the idea and a prototype was quickly up and running.

A contract for 200 cars was soon increased to 1000 units, all of which were produced in the 1966 model year.

These Hertz derivatives were supplied with special Gold sill stripes that read ‘GT350H’. Many were also kitted out with matching centre stripes. Around 80% were painted Raven Black and the remaining 20% was split primarily between Wimbledon White and Candyapple Red.

Quickly nicknamed Rent-a-Racer, some Hertz customers headed straight for the track while others swapped the powerful Shelby motors for the standard V8s in their own Mustangs.

All Hertz GT350s got Magnum 500 wheels as standard. Early examples came equipped with the Borg-Warner four-speed manual. This was replaced by Ford’s own Toploader unit after around 250 had been completed.

AUTOMATIC GEARBOX OPTION

When the C4 automatic transmission was introduced as an optional extra, many customers (including Hertz) began to order GT350s equipped as such. Autolite 4100 carbs were used for this application as opposed to the Holley 715-cfm.

GT350 CONVERTIBLE

In addition to building cars for Hertz, Carroll Shelby decided to treat himself, his secretary and a handful of close associates to a batch of specially developed GT350 Convertibles.

Not offered for public sale, six were made (all in different colours).

Chassis numbers for these cars ranged from 6S2375 to 6S2380.

PAXTON SUPERCHARGER OPTION

Eleven GT350s were also equipped new with Paxton superchargers during the 1966 model year.

Paxton’s Joe Granatelli had approached Shelby with the concept in early 1965. The idea was for a Paxton supercharger kit to be offered as an official option. Shelby lent Granatelli a ’65 GT350 (chassis 5S425) for use as a development mule.

The prototype was completed in July 1965 and Shelby was apparently bowled over by the car’s performance. He went on to order 500 Paxton kits for after-market installation.

These supercharged GT350s also came with Autolite 4100 4V carburettors and Carter high-volume fuel pumps.

Inside, there were Paxton gauges for the manifold pressure and vacuum, both of which were mounted under the centre of the dash.

With an output of between 380bhp and 400bhp, the Paxton supercharged Mustangs were the quickest road-going GT350s of all. 0-62mph took under six seconds and top speed was nearly 150mph.

1966 MODEL YEAR PRODUCTION CHANGES

The first 300 cars from the 1966 model year were completed without a GT350 badge on the tailgate.

1966 MODEL YEAR PRODUCTION

By June 1966, specifications for the redesigned 1967 model year GT350 and an even bigger-engined GT500 were finalised. Production began in September 1966.

By this time, 2388 1966 model year GT350s had been manufactured.

1368 of these were stock GT350s and 1001 were Hertz variants. There were also six Convertibles and eleven supercharged examples.

Text copyright: Supercar Nostalgia

Photo copyright: Ford - https://www.ford.com