Guide: Toyota MR2 W10 - a Historical & Technical Appraisal

/BACKGROUND

Auto manufacturers began to adopt the mid-engined layout for their small displacement sports cars in the late 1960s. By the early 1970s, models like the Porsche 914 and Fiat X1/9 were being sold in vast numbers around the world.

The popularity of these diminutive machines was enhanced by the Oil Crisis and subsequent economic gloom that took hold for much of the 1970s. Thanks to their small power units and light weight, the entry level mid-engined offerings were comparatively fuel efficient machines that offered fun, sporty motoring at a relatively low price.

Unfortunately, after an initial rash of launches, the sector went into decline; new models were slow to arrive as the market for hot hatches took over. Cars like the Volkswagen Golf GTi offered broadly similar performance in a more practical day-to-day package.

When Toyota decided to create their own small two-seat mid-engined rear-wheel drive sports car in 1979, the market was ripe for an overhaul. By this time, the Porsche 914 had been discontinued for several years. The Fiat X1/9 was long in the tooth and under powered. Small mid-engined models from Lotus were still being produced, but sales were tiny compared to what Toyota had in mind. The plan was to create a machine that commercially could rival the Nissan / Datsun Z cars that had sold in such vast numbers since 1969.

Like the Nissan Z, the new machine would prove a landmark model for Toyota.

Dubbed MR2, it was the first mass-produced mid-engined car from a Japanese manufacturer. Its name stemmed Toyota’s internal numbering system: Midship Runabout 2 seater. It would join the Celica and Supra in Toyota’s range of sporting models.

The company had first looked into feasibility of building a fun, affordable and economical car in 1976. However, poor trading conditions meant the project didn’t initially get off the ground.

It was revisited in 1979, at which point a sportier direction was taken.

The first prototype (the Toyota SA-X) emerged for internal consideration during 1981. Management soon gave the green light for a production version which arrived at the Tokyo Motor Show in October 1983. The SV-3 that went on display in Tokyo caused a sensation. Production began in June 1984, by which time the car had been re-christened the MR2.

The MR2 proved a critical success and went on to sell in huge numbers around the world.

It was introduced for the 1985 model year and initially came with a choice of two engines: an entry level single overhead camshaft 1.5 (AW10) or a dual overhead camshaft 1.6 (AW11). Both were inline four cylinder power units mounted transversely in the chassis.

Most export market MR2s would exclusively be fitted with the 1600cc engine.

CHASSIS

The MR2 was built around a complex steel bodyshell that featured a short 2320mm wheelbase and five high-strength structural bulkheads.

Toyota commissioned Lotus to help design the fully independent MacPherson strut suspension. Coil sprung dampers were fitted all round along along with anti-roll bars at either end.

Power steering was considered unnecessary.

Disc brakes were ventilated at the front (243mm diameter) and solid at the rear (240mm diameter).

Wheels measured 14 x 5.5-inches and two types were available: heavy steel rims used on some lower spec. variants and three-spoke alloy rims for most export markets and the higher JDM trim levels.

A 41-litre fuel tank was integrated within the transmission tunnel between driver and passenger.

ENGINE / TRANSMISSION

The overwhelming majority of MR2s were fitted with Toyota’s fabulous little 4A-GE engine which was packed with advanced equipment for the day.

Most notably, it featured a Yamaha-developed twin cam head with four valves per cylinder. There was also electronic port fuel-injection (supplied by Denso) and state-of-the-art T-VIS variable intake geometry.

The 4A-GE engine was extremely light and strong. The block was cast-iron and the head was aluminium alloy. Displacement was 1587cc thanks to a bore and stroke of 81mm and 77mm respectively.

With a compression ratio of 10.0:1, the naturally aspirated inline four produced a peak output of 122bhp at 6600rpm and 105lb-ft at 5000rpm.

Cars destined for the USA were equipped with a catalytic converter and vane-type air flow meter. Output dropped to 112bhp, but emissions were significantly reduced. Some other markets used a combination of these parts and typically produced between 114bhp and 118bhp.

Although the MR2 had been designed to accommodate an engine of up to two-litres, the only other power unit initially available was the entry level 3A-LU motor. It displaced 1453cc thanks to a bore and stroke of 77.5mm and 77mm respectively.

This single instead of dual overhead camshaft unit ran two valves per cylinder (as opposed to four) and had a single twin choke carburettor (instead of fuel-injection). The compression ratio was 9.3:1 (down from 10.0:1).

Peak output was 83bhp at 5600rpm and 87lb-ft at 3600rpm.

Regardless of which engine was specified, all MR2s initially came with a close-ratio C52 five-speed manual transaxle.

BODYWORK

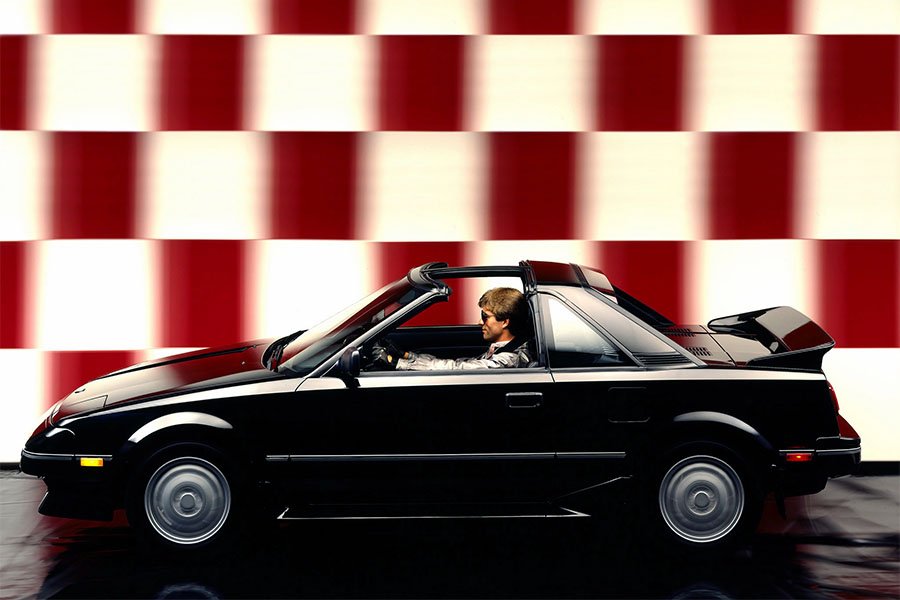

To clothe the MR2, Toyota’s stylists created a distinctive soft wedge body that went down as one of the 1980’s most recognisable designs.

The finished article was clearly an evolution of the earlier SA-X and SV-3 prototypes of 1981 and 1983 respectively.

At the front, a piercing nose was equipped with retractable headlights and a wraparound bumper underneath which was a large single air intake. More cooling solutions were carved out from down each flank and on the engine cover.

Rather than adopt a conventional fastback profile, Toyota opted for an unusual notchback design with truncated C-pillars. The A-pillars were always finished in black to give the impression of wrapround cockpit glass.

Overhangs were kept very short at either end.

In standard trim, many of the body mouldings were finished in satin black, much of which could be made body colour at additional cost.

A drag coefficient of 0.34 was achieved with the rear spoiler in place. This dropped to 0.35 if the spoiler was not present.

INTERIOR

Inside, black plastic and velour fabric were used extensively.

An arced instrument binnacle housed large read outs for engine and road speed flanked by smaller gauges for battery condition, fuel, oil temperature and water temperature. Additional toggle switches for the wipers and lights were located on the binnacle’s protruding sides.

The central console was home to the heater controls and audio system. A digital clock was recessed above a fresh air vent in the centre of the main dash.

Seats came with with colour-coded centre sections and shoulder pads.

The steering wheel was a simple twin-spoke item.

OPTIONS

Customers could enhance their cars with a variety of optional extras.

For the cockpit, Toyota offered electric windows, central locking, climate control, cruise control and a centre console storage box.

The exterior could be specified with a two-tone colour scheme, rear spoiler, retractable mirrors, retractable fog-lights, blinkers on top of the front fenders and a removable glass sunroof (which was standard in the UK).

One rarely seen option was a four-speed automatic transmission.

In Japan, customers could choose from one of four trim packages.

The entry level MR2 S came with steel wheels, no rear spoiler and no side skirts.

The MR2 G came with a few extra bits of cockpit equipment.

The MR2 G-Sport added more luxury, a choice of steel or alloy wheels plus side skirts and a rear spoiler.

The MR2 G-Limited was the most luxurious and well-equipped. Alloy wheels were standard and much of the exterior trim was body coloured. Two-tone paint was standard.

WEIGHT / PERFORMANCE

With the 1.6-litre twin cam four valve engine fitted, the MR2 weighed in at 975kg. It had a top speed of 122mph and 0-62mph time of 8.1 seconds.

The single cam two valve 1.5-litre variant was 55kg lighter (920kg). This iteration had a 106mph top speed and 0-62mph time of a little over ten seconds.

PRODUCTION CHANGES

Production got underway in June 1984 for the 1985 model year.

UK deliveries began in March 1985.

Mid way through the 1985 model year, a thicker flywheel and clutch was introduced (212mm instead of 200mm).

Upgrades and improvements were subsequently ushered in every twelve months or so.

1986 MODEL YEAR

For the 1986 model year (production of which began in June 1985), a number of changes were made.

A Toyota script was now printed on the front bumper, Toyota’s bird logo was added to the rear bumper and a rear sunshade was fitted along with a Toyota script above the rear window.

New options included a T-bar roof (Japan only) and body colouring for the front lip, bumpers, swage lines, skirts and mudflaps. Toyota also now offered leather upholstery for the seats and door cards and automatic climate control. There was additionally the option of deep full length side skirts.

Cars destined for North America now came without a rear anti-roll bar.

SUPER CHARGER

The really big news for 1986 was the addition of a supercharged version of the 1.6-litre 4A-GE engine.

Initially only offered in Japan, the new 4A-GZE power unit featured a Roots-type supercharger and a Denso intercooler. To help with fuel economy, the belt-driven supercharger was actuated by an electromagnetic clutch and only came into effect when required.

In this application, the advanced T-VIS variable intake geometry was removed and engine compression was lowered from 10.0:1 to to 8.0:1.

Peak output jumped to 145bhp at 6400rpm and 137lb-ft at 4400rpm.

To cope with the extra power and torque, a beefier E51 transmission replaced the original C52 assembly.

Externally, new eight-hole teardrop alloy wheels were fitted along with an engine cover that housed two raised banks of cooling vents.

‘Super Charger’ badges were added to the tail fascia and down each flank.

All this additional equipment meant weight rose from 975kg to 1130kg. Stiffer springs were added to compensate.

Performance figures saw top speed rise to 131mph while the 0-62mph time dropped to 6.5 seconds.

1987 MODEL YEAR

For the 1987 model year (production of which began in August 1986), the T-bar roof option was offered in markets other than Japan.

There were also some minor changes to the chassis and rear suspension, a front strut tower bar was added and the radiator was repositioned to improve airflow.

Importantly, the brake discs were enlarged from 243mm to 258mm at the front (ventilated) and from 240mm to 243mm at the rear (solid).

Externally, practically all exterior trim became body coloured as standard. There were also new tail lights for markets other than the UK and the front bumper was subtly redesigned. The rear bumper was equipped with a smaller bird logo.

Those cars fitted with a sunroof or T-top had the radio antenna moved from the roof to the right rear quarter panel.

Inside, the original two-spoke steering wheel was switched to a new small diameter three-spoke item. This was now embossed with an MR2 script as opposed to a Toyota script.

On all but base level JDM variants, the seats were switched to a single coloured fabric. When leather was specified, perforations were added to the upholstery.

Other cockpit updates included a new centre armrest, revised central air vents, revised instrument markings, an uprated audio system with speakers now housed in the C-pillars, new door panels, a lockable glovebox, new heater controls and a repositioned ashtray.

On left-hand drive cars, the parking brake was moved to the right-hand side.

Mid way through the 1987 model year, Toyota brought in several updates to the normally aspirated twin cam engine.

The original 3-rib structural design on the back of the engine was switched to a stronger 7-rib arrangement. Larger diameter bearings were used for the connecting rod big ends. The exhaust gas recirculation port was repositioned on the exhaust manifold to prevent cracking and the air intake system was completely re-routed.

Power outputs were officially unchanged although the US market derivative was now quoated with 115bhp as opposed to 112bhp.

Internals for the manual transmission iterations were revised as the same time.

Cars equipped as such are sometimes referred to as the Mk1B (as opposed to Mk1A for earlier variants).

1988 MODEL YEAR

Production for the 1988 model year started in August 1987.

At this point, the Super Charger variant which thus far had only been available in Japan was also offered in North America.

The rest of the range was enhanced with side skirts as standard.

For the Japanese Domestic Market, Toyota introduced a new Super Edition that was limited to 300 units. Based on the supercharged G Limited platform, these cars came with two-tone white over gold paint, body coloured trim and wheels, a bronze tinted windscreen, a leather wrapped Momo steering wheel and gear knob and special half leather Recaro seats.

1989 MODEL YEAR

The 1989 model year (manufactured from August 1988) was the final year of production for the original W10 MR2.

Updates included glass T-bar panels with an opaque mirrored finish (instead of smoked clear) and new more aerodynamic exterior mirrors (now with an electric option). The third brake light was switched to a bank of LEDs integrated within the rear spoiler.

The exterior mirrors and door handles were now body coloured as standard.

A rear anti-roll bar was re-instated for North American-bound cars.

There was also one more JDM special edition, again based on the G-Limited platform. These cars came with special Midnight Blue paint with gold trim, a leather Momo steering wheel and knob and Recaro seats with matching door cards. 270 were built.

END OF PRODUCTION

Production of the first generation W10 MR2 was discontinued in mid 1989.

By this time, 163,845 had been assembled in 1500, 1600 and 1600 Supercharged trim.

The W10 was subsequently replaced by the bigger and more rounded W20 derivative.

Text copyright: Supercar Nostalgia

Photo copyright: Toyota - https://global.toyota/