Guide: Jaguar XJ13 - a Historical & Technical Appraisal

/BACKGROUND

With five wins between 1951 and 1957 (two by C-types and three by D-types), Jaguar were the most successful manufacturer to participate at Le Mans during the 1950s.

Although the firm officially withdrew from motor racing at the end of 1956, they continued to supply D and E-types to privateers for competition use; the back-to-back Le Mans victories of 1956 and 1957 were actually achieved by such an outfit: Ecurie Ecosse.

Jaguar were best known for their smooth and powerful straight six engines, but a dual overhead camshaft V12 had long been under consideration. Such an engine finally came to fruition in July 1964 with a view to spawning a single overhead cam derivative for production use.

The new DOHC V12 did not go unnoticed by the experimental department’s competition workshop. Unlike earlier C and D-type motors (which were derived from production units), this latest power plant was a fully fledged racing engine designed to push the V12 concept to its technical limit.

1964 was a watershed season for sportscar racing. Ferrari had largely dominated the scene since Jaguar’s exit, but a new Anglo-American challenger emerged at the Le Mans Test that April: the Ford GT40.

Henry Ford II had sanctioned the multi million dollar GT40 programme after Enzo Ferrari reneged on a deal to sell his company. Thus began perhaps the greatest battle in sportscar history.

Compared to the single cam Ferrari V12 and Ford’s pushrod V8, the new Jaguar V12 seemed to have an edge. Understandably, the competition department in Coventry thought it the ideal power unit for an all new prototype racing car that could return Jaguar to Le Mans.

A small team started work on designing a brand new mid-engined challenger: the XJ13.

While never a priority for management, it was hoped the creation of a promising prototype might change minds.

CHASSIS

The XJ13 was based around an all new aluminium monocoque chassis with a 2410mm wheelbase. The engine and gearbox were used to carry the rear suspension while the front assembly was attached to a bolt-on subframe.

Front suspension was via double wishbones. At the back, the driveshafts were used as upper transverse links (similar to the E-type) with two radius arms per side and a single transverse lower link. Coil sprung Armstrong dampers were fitted all round.

Ventilated disc brakes were supplied by Dunlop; they had a 303mm diameter at the front and 295mm diameter at the rear.

Two enormous fuel tanks with a combined capacity of 41 gallons (186.4-litres) were located either side of the engine, up against the rear bulkhead.

Handsome five-spoke magnesium alloy wheels measured 15 x 7 inches at the front and 15 x 9.375-inches at the rear. They were shod with Dunlop R7 racing tyres.

ENGINE / TRANSMISSION

Jaguar’s Claude Bailey-designed 60° V12 was essentially two XK six cylinder engines on a common crankshaft, albeit with differences to the inlet porting, valve angles and shape of the combustion chambers.

The engine comprised an aluminium alloy block and head with dry-sump lubrication and dual overhead camshafts for each bank of cylinders.

Displacement was 4994cc thanks to a bore and stroke of 87mm and 70mm respectively.

Electronic ignition came courtesy of the new Lucas OPUS system. The compression ratio was 10.4:1.

Initially, six SU sidedraught carburettors were used and the engine developed 445bhp at 7000rpm.

Jaguar soon switched to Lucas mechanical fuel-injection which led to a marked increase: 503bhp at 7600rpm. In this configuration, the peak torque rating was 382lb-ft at 6300rpm.

With careful development, Jaguar’s engineers thought another 200bhp might be possible.

The first engine ran in July 1964. In total, seven prototype motors were built. Early iterations featured chain drive to the cams while later versions used gear-driven cams.

A five-speed manual ZF 5DS-25 transaxle was employed.

BODYWORK

The XJ13’s aluminium bodywork was designed by feted aerodynamicist, Malcolm Sayer, who had previously been responsible for both the C and D-type.

Standing precisely one metre high, the XJ13 had an extremely low drag coefficient (0.29) which compared favourably with anything Ford or Ferrari had to offer.

At the front, a gaping oval intake fed air to an enormous radiator. The front lid was home to a NACA duct and four separate banks of cooling louvres. Headlights were positioned underneath Plexiglas covers.

Shoulder-mounted rear wing intakes fed fresh air into the engine bay, but unlike most sports racing cars of the era, Sayer eschewed a Kamm tail in favour of a pointed rear end with E-type lights.

The four cam V12 was enclosed underneath a fastback Plexiglas cover that could quickly be removed for easy access. The clear engine cover was neatly integrated with a basket handle roll over hoop.

Bodywork was fabricated from aluminium by Abbey Panels just down the road in Coventry. Exposed rivets were a feature of both the interior and exterior.

INTERIOR

The roofless cockpit was home to a pair of black bucket seats upholstered with vinyl bolsters and velour centres. The other cabin surfaces were left as bare metal.

To increase space none of the instrumentation or switchgear was located behind the wood-rimmed three-spoke steering wheel. Instead, the majority of dials and levers were angled towards the driver in a pod located ahead of the passenger seat.

A large 10,000rpm rev counter was accompanied by smaller gauges for oil pressure, oil temperature, fuel and water temperature. The 240mph speedometer was almost impossible to read as it was located around the corner from this main bank of instrumentation.

WEIGHT / PERFORMANCE

Although at 1040kg, the XJ13 prototype was a little on the heavy side, it could still hit 195mph. 0-62mph took under four seconds.

JAGUAR MERGES WITH THE BRITISH MOTOR CORPORATION

In mid-1965, Pressed Steel Company Ltd. which made all Jaguar’s monocoques was purchased by the British Motor Corporation (BMC).

Concerned about the ongoing threat of supply, Jaguar founder and managing director, Sir William Lyons, accepted BMC’s offer to merge the two firms to form British Motor (Holdings) Limited.

The merger was announced on 11th July 1965.

THE XJ13 TAKES A BACK SEAT

By this time, the XJ13 project was running behind schedule and thereafter became even less of a priority for management.

Now working mostly evenings and weekends, the small team had the first car running in March 1966. However, with few staff, little time and an almost non-existent budget, it wasn’t until a year later that testing began in earnest.

Nine tests were variously held at Silverstone and MIRA between March and August of 1967.

Ex-Jaguar apprentice, David Hobbs, carried out the lion’s share of the driving. At MIRA, he achieved an unofficial UK closed lap record which stood for 32 years. It was eventually beaten by the McLaren F1.

The final test took place at Silverstone where Hobbs was joined by fellow ex-Jaguar apprentice, Richard Attwood.

THE FIA BANS OVER 3-LITRE PROTOTYPES

Unfortunately, just a few weeks earlier, the FIA had dropped a bombshell that killed any prospect of the XJ13 ever going racing.

The day after Le Mans, it was announced a three-litre engine limit would be imposed on Group 6 Prototype racing cars from 1968 in an effort to reduce speeds. The decision was made without any manufacturer consultation, but top flight prototypes had become so fast that the governing body felt drastic action was needed.

As a consequence, a whole raft of cars were made obsolete practically overnight.

Vehicles with engines of up to five-litres could still race, but now only in the Group 4 Sports car category where 50 units were required to secure homologation.

Following its final Silverstone test, the XJ13 was put into storage.

SUBSEQUENT HISTORY

The car was forgotten about until 1971, when Jaguar were ready to launch their first V12-powered production model: the Series 3 E-type.

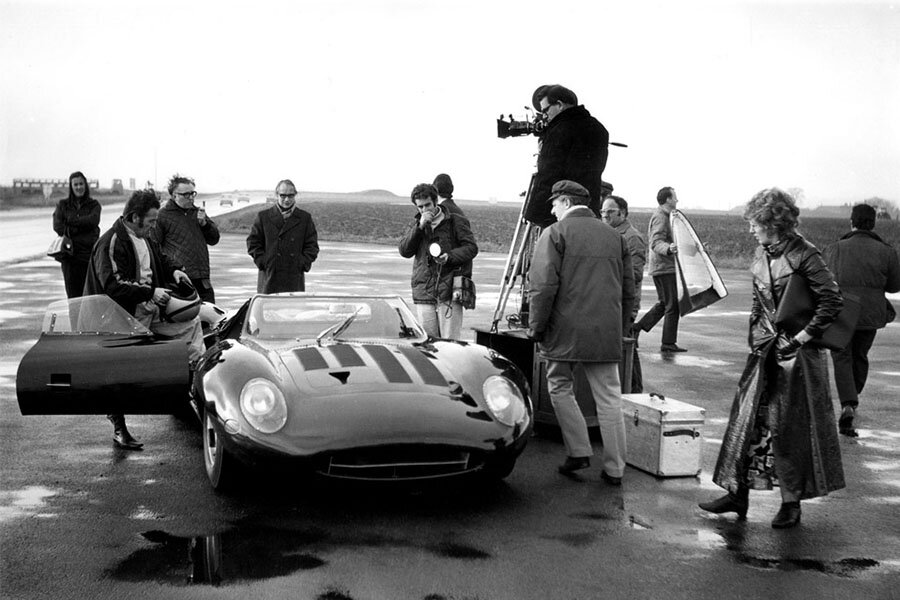

Jaguar’s publicity team were making a promotional film for the new model and wanted footage of the XJ13 at speed for the opening sequence. Fitted with a set of unused wheels on fresh tyres, the car was trucked to MIRA where test driver, Norman Dewis, took the reins.

Unbeknown to Dewis, one of the lightweight magnesium wheels had already begun to corrode from the inside. On the final lap of filming, the wheel failed, which sent the XJ13 into a retaining fence from where it rebounded and barrel rolled before coming to rest on its wheels.

Although Dewis was miraculously unharmed, the XJ13 was heavily damaged.

It was subsequently put back into storage until 1973, at which point the car was rebuilt by Abbey Panels using the original jigs.

The restored car made its debut at Silverstone during the 1973 British Grand Prix where Lofty England drove it for a number of parade laps.

Today, the XJ13 forms part of Jaguar’s Heritage Trust museum in Gaydon, Warwickshire.

Text copyright: Supercar Nostalgia

Photo copyright: Jaguar Heritage Trust - https://www.jaguarheritage.com/