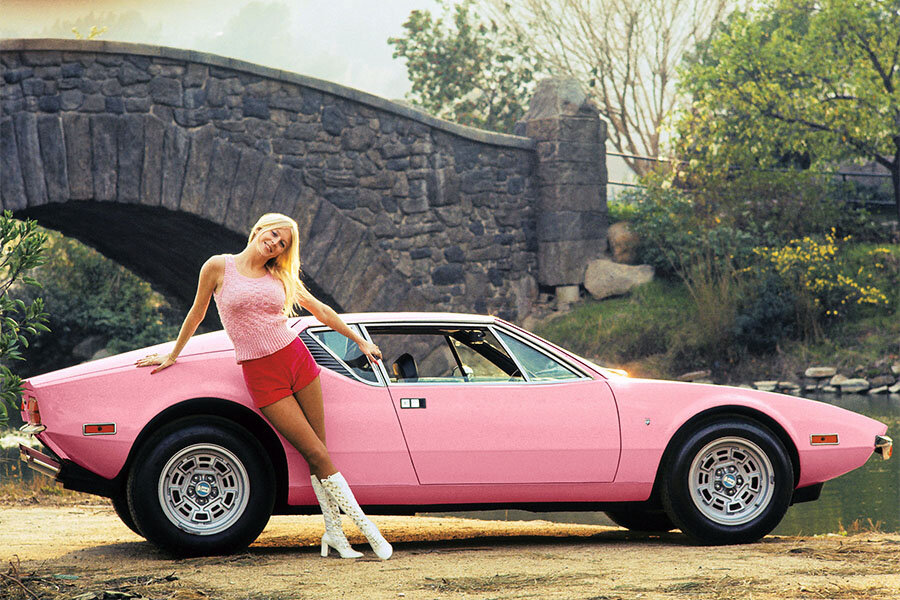

Guide: De Tomaso Pantera - a Historical & Technical Appraisal

/BACKGROUND

Since his company’s 1959 inception, Alejandro de Tomaso had skipped from one project to the next. Myriad Formula, Sports and concept cars had emerged, but it was not until the Ghia-built Vallelunga arrived in 1964 that a single model had entered what could legitimately be described as ‘production’.

50 Ghia-bodied Vallelungas were ultimately produced.

The Vallelunga was built on a spine chassis with a mid-mounted Ford 1500cc four cylinder engine.

De Tomaso then used the same layout for their handsome but chronically under-developed Mangusta, deliveries of which began in late 1967. Despite its foibles, 401 of the Ford V8-powered Mangustas had been manufactured by the time production ended in 1971.

During 1969, De Tomaso began the process of creating a successor to the Mangusta. Although similarly powered by a mid-mounted Ford V8 engine, the Tipo 874 Pantera would employ a pressed steel monocoque which was stronger and easier to build.

For many years, Alejandro de Tomaso had sought investment from a major car manufacturer. He had already courted the Ford Motor Company with the Mangusta, but in view of its compromised nature, no collaboration was forthcoming.

The Pantera, however, was a different matter.

It caught the attention of Lee Iacocca, head of Ford Division and the brains behind the Mustang.

Iacocca desperately wanted Ford to offer a mid-engined model before rivals General Motors and American Motors.

With its off-the-shelf powertrain and Italian heritage, Iacocca thought Ford could sell 5000 Panteras every year.

Ford ultimately went on to purchase 80% of De Tomaso Automobili and also invested heavily in the Ghia coachworks that Alejandro de Tomaso had taken control of in 1967.

When the Pantera was publicly unveiled at the New York Motor Show in April 1970, it was just a few months away from entering production.

At this stage, the only other mid V8 or V12-engined model available from an Italian manufacturer was Lamborghini’s wickedly expensive Miura.

Flagship mid-engined models from Ferrari and Maserati would not enter production for another couple of years; it seemed that Ford would not only steal a march on their domestic rivals but on the Italian aristocracy as well.

In the USA, Ford planned to sell the Pantera through its Lincoln Mercury dealerships. The car would also be available in Europe through De Tomaso’s existing sales network.

The production process involved the rear subframe (made by outside contractors) being sent to Vignale where the rest of bodyshell was fabricated. Bodies were primed, painted, fitted with glass and interiors and then trucked the 250 miles from Turin to the new De Tomaso factory in Modena. Here they were united with a drivetrain and suspension before dispatch.

CHASSIS

The Tipo 874 steel monocoque with its 2500mm wheelbase and square tubed rear subframe was equipped with fully independent suspension designed by Giampaolo Dallara. Double wishbones, coil springs and telescopic dampers were fitted all round along with anti-roll bars at either end.

Servo-assisted disc brakes came with Girling calipers sourced from England.

Steering was by a rack and pinion system but there was no provision for power assistance.

An 85-litre fuel tank was mounted in the left-hand side of the engine bay up against the rear bulkhead.

To save cash, many existing parts were bought in from outside manufacturers but the Pantera’s expensive cast magnesium wheels were brand new. Custom designed by Campagnolo, they measured 15 x 7-inches at the front, 15 x 8-inches at the back and were originally shod with Pirelli or Michelin tyres.

ENGINE / TRANSMISSION

The 5.8-litre V8 used by De Tomaso was manufactured at Ford’s Cleveland factory in Ohio.

Originally created for use in high performance Mustangs and Mercury Cougars, it featured a cast iron block and head with pushrod actuated overhead valves.

These early cars came with an engine that featured two-bolt main bearing caps.

Other equipment included forged steel rods, large canted valves, wedge-shaped combustion chambers in the cylinder heads, light aluminium-alloy pistons and a cast iron intake manifold.

Displacement was 5763cc thanks to a bore and stroke of 101.6mm and 88.9mm respectively.

Compression was initially 11.0:1 and a four-barrel Autolite carburettor was fitted.

Special De Tomaso-branded valve covers were added along with a more efficient exhaust manifold.

In this configuration, peak output was 330bhp at 5400rpm and 380lb-ft at 3400rpm.

Transmission was via a ZF 5DS-25/1 five-speed manual gearbox, hydraulic single plate clutch and limited-slip differential.

A removable felt-lined fibreglass luggage tray was mounted above the transaxle.

BODYWORK

The steel bodywork was designed by Tom Tjaarda at Ghia. Fabrication took place at Vignale.

The Pantera followed the burgeoning wedge trend for angular coachwork. This was a direct contrast to the curvaceous machinery that came to define the previous two decades of auto design.

Retractable headlights were a fashionable addition. They were located above small chrome bumperettes that neatly shrouded the indicators. The front lid opened to reveal a small additional luggage area.

Dummy intakes were located behind each three-quarter window.

Tjaarda added satin black sills to give the Pantera a more slender profile.

The entire upper rear body section could be raised for access to the engine bay and storage bin.

A handsome tail fascia was home to Carello tail lights and a two-piece bumper.

Chrome was used for the window frames, push button door catches, bumpers, windscreen wipers, front grille shroud and model script.

US versions came with additional side marker lights.

INTERIOR

The interior was a strange mix; while electric windows and air-conditioning were standard, the vinyl upholstery felt a little cheap and there was no leather option.

Although some European market Panteras came with a two-spoke steering wheel, most cars were equipped with a padded three spoke wheel from the American Ford Capri GT.

Well-padded seats could be adjusted fore and aft but the backs were fixed in position.

The 8000rpm tach and 200mph speedometer were located in twin cowls directly behind the steering wheel. Supplementary gauges for oil pressure, water temperature, fuel and battery condition were stacked vertically on the centre console alongside a variety of rocker switches to include the window controls.

Radios (installed by the supplying dealer) were mounted vertically on the centre console under the ventilation system.

WEIGHT / PERFORMANCE

De Tomaso quoted a weight of 1420kg, a top speed of 162mph and 0-62mph time of 5.5 seconds.

PRODUCTION CHANGES

The first production cars were delivered in early 1971.

As a result of poor early quality control, Ford soon increased their involvement and introduced precision stampings for the body panels.

Other changes included the switch to conventional door catches (sourced from Fiat). These replaced the early push-button releases that required a recessed element behind each door.

Extra slots were cut into the Campagnolo wheels, new tail lights were fitted and, from mid 1971, new gearbox ratios were introduced.

1972 UPDATES

For 1972, a series of more far-reaching modifications were introduced.

Most significant was the arrival of an engine with four-bolt main bearing caps. The factory headers were replaced with simpler exhaust manifolds that featured webbing between the individual pipes.

To meet US emissions standards, compression was lowered from 11.0:1 to 8.6:1.

To claw back some of the lost horsepower, a more aggressive Cobra Jet camshaft was installed.

However, output dropped to 296bhp at 6000rpm.

At the same time, a dual instead of single point distributor was fitted, the clutch linkage was modified for ease of use and the brake fluid reservoir was integrated with the master cylinder.

So it could more easily be removed, the rear luggage tray bolts were switched to quick release screws.

Various cables were re-routed and the oil level dipstick was lengthened. Fans were switched from manual to automatic and splash shields were installed to eliminate water ingress over the fuel tank, horns and radiator fans.

END OF PRODUCTION

Production continued until mid 1972 at which point the revised Pantera L was introduced.

By this stage, an estimated 3643 of these first generation Panteras had been completed.

Text copyright: Supercar Nostalgia

Photo copyright: De Tomaso Automobili - https://detomaso-automobili.com/